Wet Cast Stone

Our product range

Why choose wet cast stone?

Our wet cast stone manufacturing process offers a proven, uncompromised balance of strengths that can be fine-tuned for every project.

The wet cast stone manufacturing process provides a close grained, smooth and dense surface which offers precise rendering of fine details. The mix of raw materials in this process uses considerably more water than in the semi-dry process, and offers a through colour homogenous mix which exposes the natural aggregate colours within the material when etched. This gives the finished stone the look and feel of quarried natural stone.

With 60 years' experience Vobster Architectural have a well-established reputation for producing only the highest quality materials for use in a wide range of construction projects including retail, residential and commercial schemes. Our technical team can provide expert advice for stonework and fixing design, and then later support the contractor through the installation phase.

Bespoke design and product features

Wet cast stone holds structural units with high compressive and tensile strengths thanks to the inclusion of bespoke high specification cast-in reinforcing. Intricate and crisp designs can be achieved on any scale; even on units weighing up to 10 tonnes.

Our wide choice of natural fine finishes can be created and tailored to suit individual and bespoke requirements. Our wet cast stone is easy and cost effective to maintain over the long term due to the reduced permeability of the material that virtually locks moisture out.

Wet cast stone is strong and durable to levels that far exceed British Standard guidelines, while maintaining the natural beauty of stone. Our robust solid timber, steel, fibreglass or polyurethane moulds can be formed to achieve almost any shape or profile.

For more information, or to arrange samples, contact our team who will be happy to help.

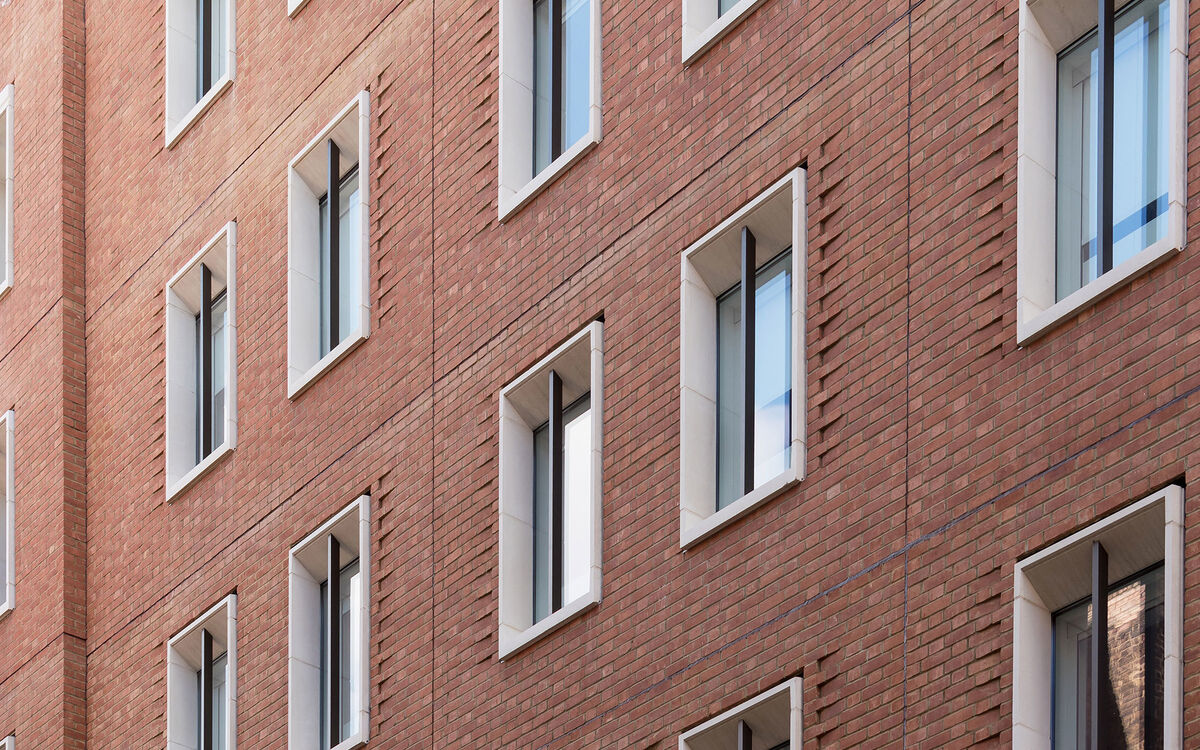

Wet Cast Stone / Design gallery

1 / 18

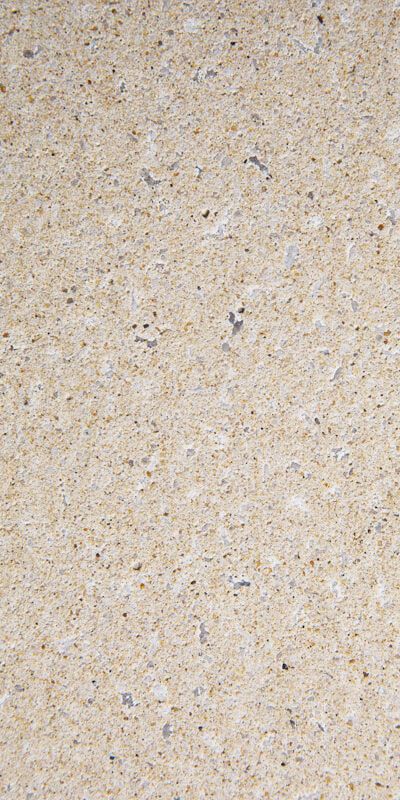

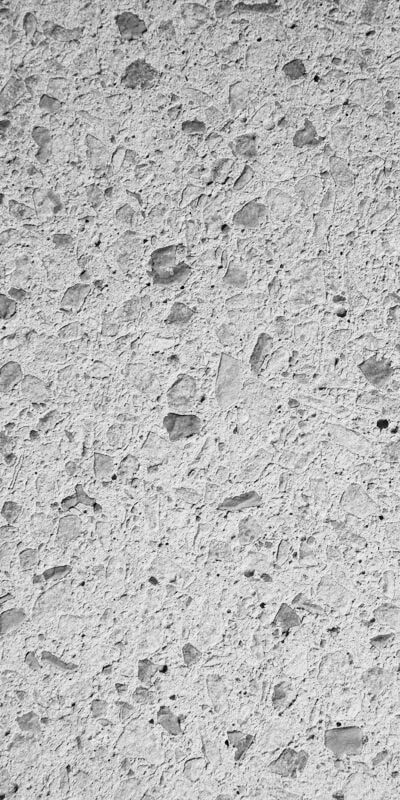

Textures and finishes

to suit any project

1 / 6

Our unrivalled Quality and Design processes…

Our trademark high-quality moulds provide a flat, dense, close-grained surface, which is ideal for creating a variety of precise finishes and the finest detail, accurately and consistently. Our wet cast products are also extremely strong and durable, so they can be used as a structural element without any additional support, bringing significant construction and economic benefits.

Once casting is complete, we etch the seen faces to expose the beautiful, authentic colours inherent in the Portland and Bathstone aggregates. They contain no pigmentation and simply reflect the timeless look and feel of natural quarried stone through a broad variety of finishes.

“We are already recommending Vobster Architectural to all our contacts and clients. In our opinion its product and service are the best on the market.”

Adam Rowland, Rowland Stonemasonry

More products

We’d love to hear from you

To request a sample or speak to a member of our team, get in touch with our office who will be happy to support you and answer any questions you may have.

T. +44 (0)203 968 7058 E. enquiries@vobsterarchitectural.co.uk

Contact us